Module 2: Sucker-Rod Pumping Systems

Beam units, rod strings, and downhole pump mechanics.

🎯 Learning Objectives

- Explain how beam units convert rotary to reciprocating motion.

- Identify the function of the rod string and downhole pump valves.

- Estimate production rate using Q ≈ A × Stroke × SPM × Fillage × 1440 × η.

- List common operational issues (gas interference, wear) and mitigations.

📘 Key Terms

SPM

Fillage

Traveling valve

Standing valve

Polished-rod load

📎 Prerequisite

Module 1 — Intro to Artificial Lift

ℹ️ What & Why

Sucker-rod systems use a surface beam unit to drive a reciprocating downhole pump. They are the most widely deployed lift method, spanning low-rate land wells to large fields, thanks to simplicity, maintainability, and cost effectiveness.

⚙️ Principles of Operation

- Beam/gearbox converts rotary motion to a vertical stroke at the polished rod.

- Rod string transmits the motion to the downhole pump barrel & plunger.

- Upstroke: traveling valve closes; fluid passes the standing valve and lifts.

- Downstroke: traveling valve opens; chamber fills for the next cycle.

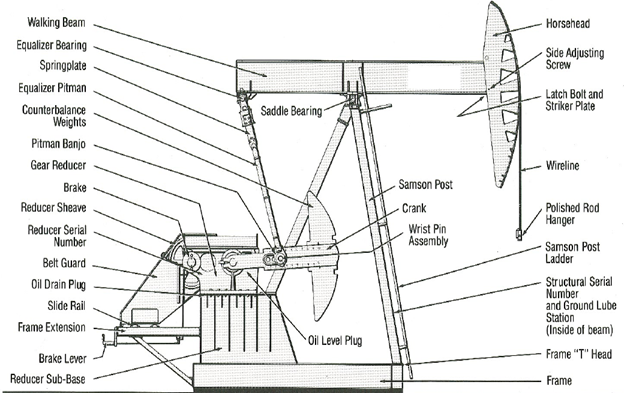

🧩 System Components

- Surface unit (beam + gearbox) and prime mover (motor/engine).

- Sucker-rod string (graded/tapered) to manage load and wear.

- Downhole pump with traveling & standing valves.

- Tubing anchor / seating nipple for pump placement.

- Wellhead & polished-rod seal for load transfer and sealing.

📏 Operating Considerations

💡

Field Tip

Start with moderate SPM and tune for fillage & efficiency before increasing rate.⚠️

Common Pitfall

Ignoring gas interference at the pump intake reduces fillage and increases loads.

Add separation strategies where needed.🧪 Worked Example — Estimating Rate

Formula

Q ≈ Aplunger × Stroke × SPM × Fillage × 1440 × ηvol

Given: Plunger Ø = 1.5 in → A = 1.767 in²; Stroke = 100 in; SPM = 8; Fillage = 0.85; ηvol=0.9.

Compute: Q ≈ 1.767 × 100 × 8 × 0.85 × 1440 × 0.9 / 231 ≈ ~850 bpd (approx.).

231 in³ = 1 gallon; 42 gal = 1 bbl. Use detailed corrections for slip/compressibility in practice.

Tip: Click any figure to open the full-size image in a new tab.

✅ Quick Knowledge Check

1) Which component converts rotary to reciprocating motion?

The surface beam + gearbox provides the reciprocating stroke.

2) Low pump fillage is most commonly due to…

Gas at the intake reduces effective intake volume; separation helps.

3) Spot the mistake (Worked Example): Which change most directly increases Q?

Q scales with SPM and stroke while fillage & efficiency remain high.

🧾 Summary & Takeaways

- Beam/gearbox creates a reciprocating stroke that drives the downhole pump.

- Traveling/standing valves control intake and lift across strokes.

- Rate scales with A, stroke, SPM, fillage, and volumetric efficiency.

- Watch for gas interference, deviation wear, and excessive loads.

- Tune SPM and separation first; then optimize rod design and pump size.

➡️ What’s Next

Up next: Module 3 — Electrical Submersible Pumps (ESP)

Recommended: skim a vendor beam-pump manual; review your field’s SPM/fillage trends.

Last updated: Aug 2025 • Author: Atlas ESP Academy